2018-08-13 Conloon 0

Electric Refrigeration Dehumidifiers

Electric refrigeration dehumidifiers are the most common type of dehumidifiers. They work by drawing moist air over a refrigerated evaporator with a fan. There are 3 main types of evaporators. They are coiled tube, fin and tube, and microchannel technology.

The cold evaporator coil of the refrigeration device condenses the water, which is removed, and then the air is reheated by the condenser coil. The now dehumidified, re-warmed air is released into the room. This process works most effectively at higher ambient temperatures with a high dew point temperature. In cold climates, the process is less effective. Highest efficiency is reached above 20 °C (68 °F) and 45% relative humidity. This relative humidity value is higher if the temperature of the air is lower.[citation needed].

This type of dehumidifier differs from a standard air conditioner in that both the evaporator and the condenser are placed in the same air path. A standard air conditioner transfers heat energy out of the room because its condenser coil releases heat outside. However, since all components of the dehumidifier are in the same room, no heat energy is removed. Instead, the electric power consumed by the dehumidifier remains in the room as heat, so the room is actually heated, just as by an electric heater that draws the same amount of power.

In addition, if water is condensed in the room, the amount of heat previously needed to evaporate that water also is re-released in the room (the latent heat of vaporization). The dehumidification process is the inverse of adding water to the room with an evaporative cooler, and instead releases heat. Therefore, an in-room dehumidifier will always warm the room and reduce the relative humidity indirectly, as well as reducing the humidity more directly, by condensing and removing water.

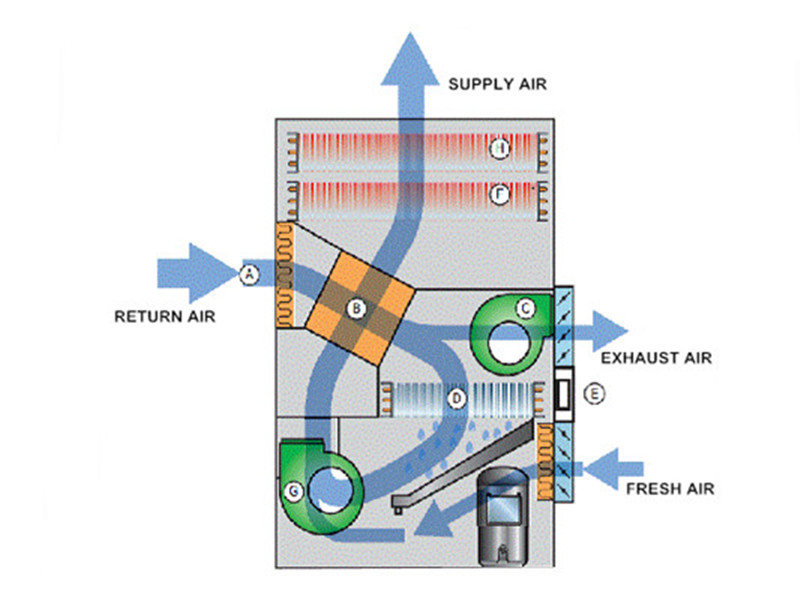

Warm, moist air is drawn into the unit at A in the diagram above. This air passes into a crossflow plate heat exchanger (B) where a substantial proportion of the sensible heat is transferred to a cool supply air stream. This process brings the extracted air close to saturation. The air then passes to the plenum chamber of the extract fan (C) where a portion of it may be rejected to outside. The amount that is rejected can be varied and is determined either by legislation on fresh air requirements, or by the requirement to maintain a fresh, odour free environment. The balance of the air then passes into the evaporator coil of the heat pump where it is cooled and the moisture is condensed. This process yields substantial amounts of latent energy to the refrigeration circuit. Fresh air is then introduced to replace the amount that was extracted and the mix is discharged by the supply fan (G) to the crossflow plate exchanger (B) where it is heated by the extract air from the pool. This pre-warmed air then passes through the heat pump condenser (F) where it is heated by the latent energy removed during the condensation process as well as the energy input to the compressor. The warm dry air is then discharged to the room.